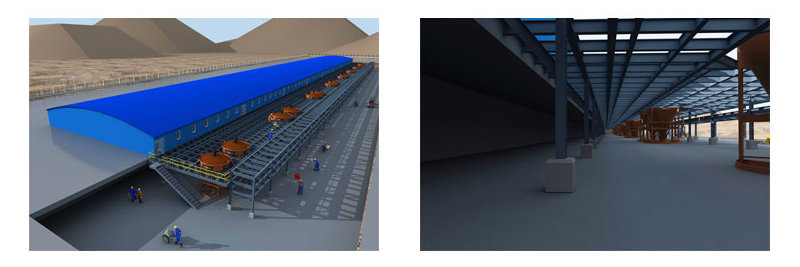

Large Modern Prefab Metal Shed

Brand SYLY

Product origin China

Delivery time 30working days

Supply capacity 5000tons/month

1. The steel structure large prefab shed has the characteristics of no leakage: whether it is welded, riveted or bolted, the steel structure can be sealed without leakage

2. Factory-based steel structure modern prefab shed manufacturing and assembly-based construction: light components, convenient construction, small site occupation, short construction period, and easy demolition, reinforcement, reconstruction and expansion.

3. The steel structure prefab metal shed is light in weight and high in bearing capacity: it is a lightweight and high-strength material.

Product Name | Large Modern Prefab Metal Shed |

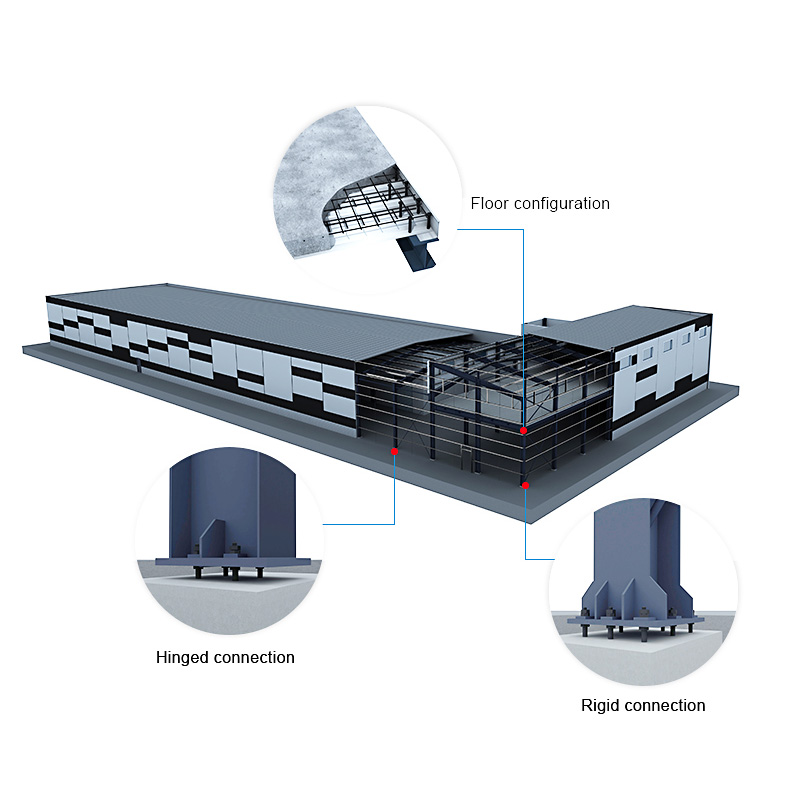

Main Steel Frame | H section steel beam and columns, painted or galvanized, galvanized c section or steel pipes. |

Secondary Steel Frame | Hot dip galvanized c purlin, steel bracing, tie bar, knee brace, edge cover, etc. |

Roof or Wall Panel | EPS sandwich panel, glass wool sandwich panel, rock wool sandwich panel, and PU sandwich panel or corrugated steel sheet. |

Tie Rod | Circular steel tubes |

Brace | Round bar |

Knee Brace | Angle steel |

Roof Gutter | Color steel sheet |

Windows | PVC frame or aluminum alloy frame windows |

Doors | Sliding sandwich panel door or rolling metal door or vertical hinged door |

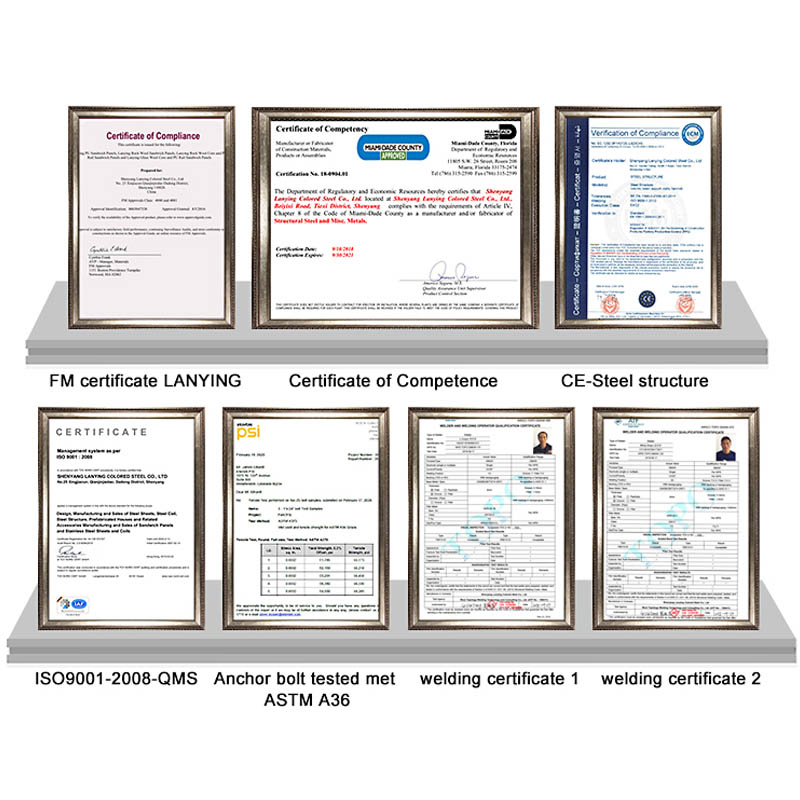

Certification | CE, SGS, ISO9001:2000 |

Connecting | Post feet bolts, anchor bolts, intensive bolts and machine bolts |

Packing | According to the pack list made by our engineer |

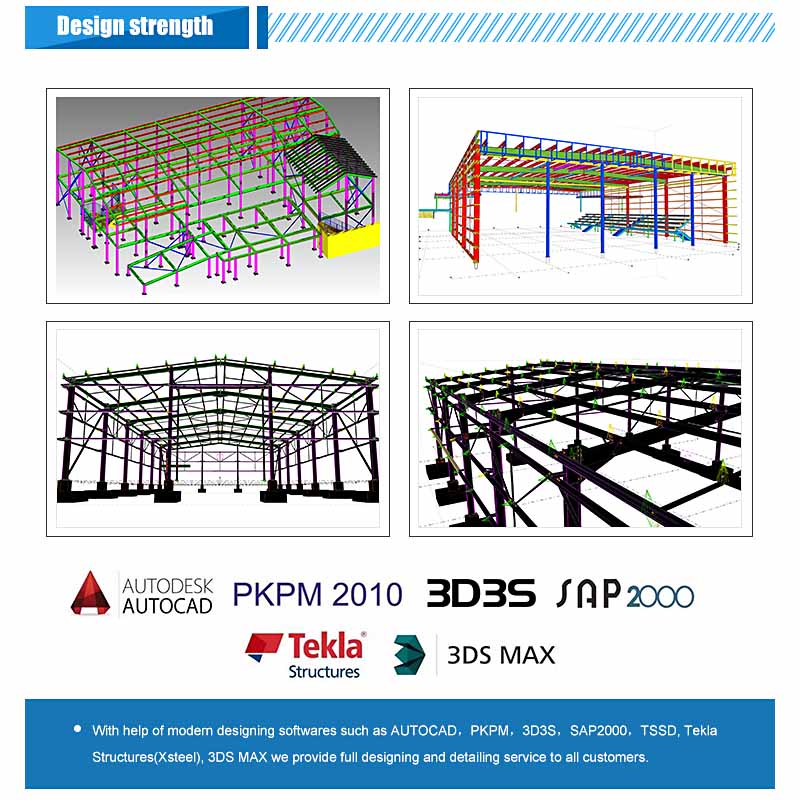

Drawings | CAD drawings |

Quotation | We can make the design and quotation according to your require or your drawing. |

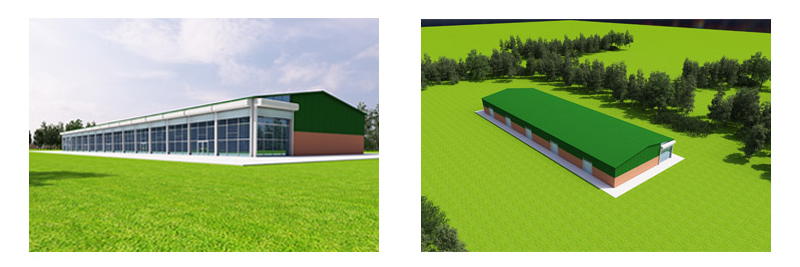

Steel school building

When it comes to the safety of the children in your school, there is no stronger or more durable construction material than steel.

Promising the best value for your dollar, a steel building is the best option for steel school building divisions on a limited budget. Using steel for your new prefab school building can result in savings of up to 50% on the cost of construction compared to other building materials. Steel is also one of the most durable materials available, guaranteeing your prefab school building to last for many years. As steel requires minimal upkeep compared to wood, your maintenance costs will also be comparatively lower than other construction materials, leading to future cost-savings for many decades to come.

When it comes to putting children’s safety first, steel is one of the strongest and sturdiest construction materials on the market. Safe against earthquakes, strong winds, hurricanes, and even fires, your students’ safety and security will be guaranteed in a pre-engineered steel school building.

Whether you are choosing a pre-engineered steel building to add on to your school’s existing space, as an entirely new replacement building, or as a new charter school, its exterior can be customized to suit any surroundings. From stone to brick, hardy board & stucco your finishing options are limitless with a steel building.

1. The steel structure large prefab shed has the characteristics of no leakage: whether it is welded, riveted or bolted, the steel structure can be sealed without leakage

2. Factory-based steel structure modern prefab shed manufacturing and assembly-based construction: light components, convenient construction, small site occupation, short construction period, and easy demolition, reinforcement, reconstruction and expansion.

3. The steel structure prefab metal shed is light in weight and high in bearing capacity: it is a lightweight and high-strength material.

Quote information

Could you tell me your requirement for your steel structure project?

Basic design requirements and design Load,

1. Project site location:

2. Overall dimension (length*width*eave height in meters):

3. Mezzanine of not? How many kgs of load per square meter on mezzanine?

4. Single-layer steel sheet wall or sandwich panel wall:

5. Snow load if applicable:

6. Wind speed/load:

7. Interior column allowed or not:

8. Overhead crane needed or not, capacity:

9. Any other particular requirements:

Certifications

Company Profile

Our group headquarters is located in Shenyang. Our manufacturing facilities are located in Liaoning, Shandong, Hebei, and Heilongjiang. We have the best quality of manufacturing equipment and a group of outstanding technical personnel. We have accumulated a wealth of practical experience in steel structure fabrication and installation and passed ISO9001:2000 quality management system certification.

With the purpose of “Market is the lead, Quality is the center, Treat the client with friendly service”, our company has become a modern enterprise integrating with manufacture and construction as a whole. Our company offers the whole set of services of all kinds of light steel buildings including design, manufacture, and construction. Our company emphasizes contract complying with credibility with rigorous product manufacturing processes.

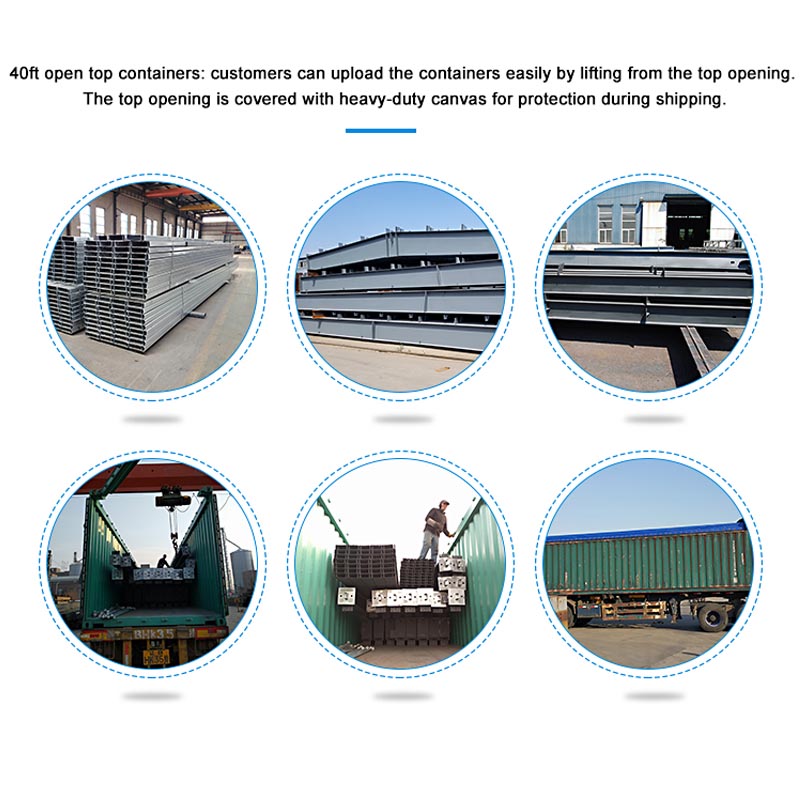

Packing Logistics

Fixed packing, loading, transportation, unloading the matters needing attention:

(1) The lifting large there must be a person responsible for the use of fixture, suitable, strictly abide by the rules of lifting, to prevent the occurrence of vibration, impact, deformation or damage, fall in the hoisting process.

(2) At the time of loading, there must be a special supervision, check car number and packing, the car pile up securely, and to increase the necessary binding component loosening, prevent the loss.

(3) Remained stable in the transport process, the vehicle at the time of shipment, on the long, wide, high object transport, must be trained pilots, escort personnel responsible for, and mark is arranged on a vehicle.

(4) No rough handling, loading and unloading personnel handling, weight, size should be familiar with the components, and check the horse sling, rigging, prevent accidents.

(5) The member to the construction site, timely organization of unloading, stacking area.

(6) The crawler crane carrying member, should pay attention to the surrounding terrain, air condition, prevent the crawler crane overturning and component collision.

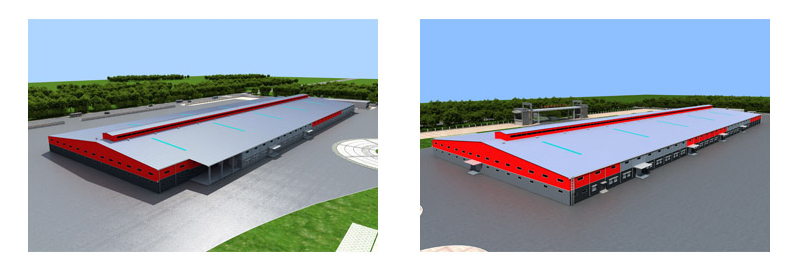

Project Cases

Steel structure building project in the USA

Steel structure building project in the Georgia

Steel structure building project in the Democratic Republic of the Congo

Steel structure building project in Mozambique

Steel structure building project in Togo