Light Steel Structure Warehouse Manufacturing Cost

Brand SYLY

Product origin China

Delivery time 30 working days

Supply capacity 5000 tons/month

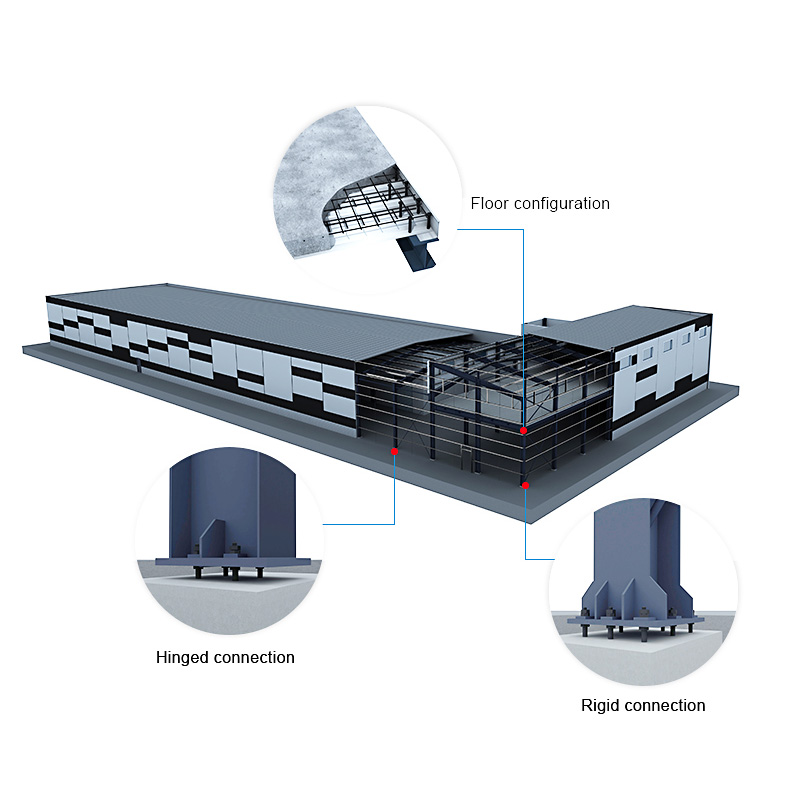

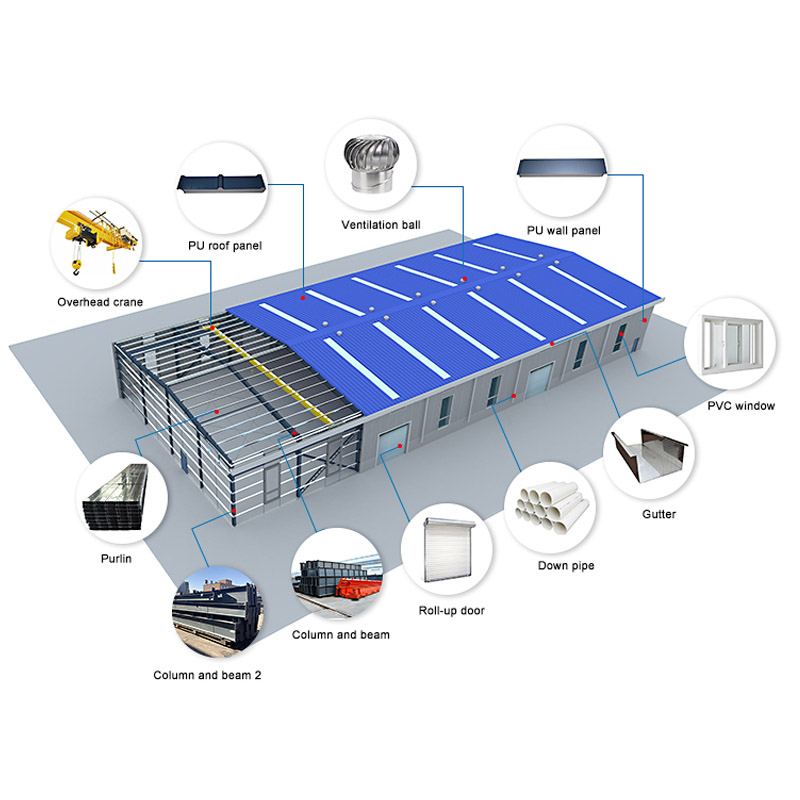

1. Light steel structure warehouse Safe, robust, and durable buildings - local and national building codes are always considered in design and engineering to ensure that each metal building can meet or exceed all structural requirements required by the specific environmental conditions of the worksite and application.

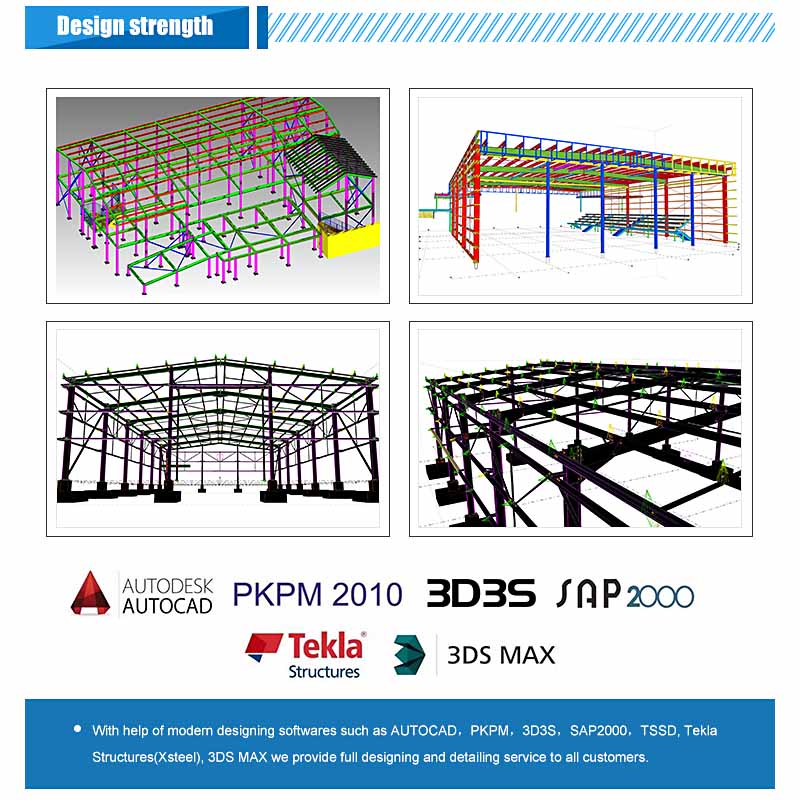

2.Pre-design to improve cost-effectiveness – the pre-design process can create metal structures with little waste, using only the exact amount of steel required for each specific light steel warehouse.

3. Easy to assemble - when your prefabricated steel structure arrives at your worksite, all components will be properly packaged, bundled, and clearly labeled. At the beginning of construction, each component will be quickly located and cross-referenced in the blueprint and installation manual. Moreover, there is no welding and small cutting on-site, and each component fits perfectly with each other, making the structure very easy to assemble warehouse manufacturing cost.

Quick Details

Type | workshop | Warranty | 3 years |

Afrer-sale Service | Online technical support Onsite Installation Onsite Training Onsite Inspection Free spare parts, Teturn and Replacement | Project Solution Capability: | graphic design 3D model design Total solution for projects Cross Categories Consolidation |

Standard | GB standard | Design Style | Transitional |

Place of Origin | Liaoning, China | Brand Name | SYLY |

Certificate | ISP9001:2008 | Purlin | C shape purlin |

Wind loading | 200km/h | Life time | 50 years |

Surface treatment | Anti-rust painting or galvanized | Door | Rolling door or sandwich panel door |

Roof and wall | Single layer sheet or sandwich panel | Window | PVC or aluminium window |

Products Description

Items | Steel Workshop Buildings |

Main structure | PEB welded H-shaped steel or hot rolled steel, Q355 or Q235 |

Anti-rust protection | Hot dip galvanized or anti-rust painting |

Purlin and girts | Cold rolled C or Z steel, Q355 or Q235 |

Roof and wall | Single layer steel sheet or sandwich panel |

Gutter | Heavyduty galvanized steel |

Downpipe | PVC |

Door | Sliding door or roller shutter |

Windows | PVC or aluminum alloy |

Other components available upon request. Please provide the following information for detailed custom design. | |

Steel structure Workshop

Whether it’s for a business or private use, a metal workshop is a valuable addition to any property. General Steel provides the materials and resources to complete a professional building project that will thrive under any circumstances. Workshops are among the most popular buildings we sell because of the versatility, efficiency, and high-quality steel construction of a General Steel building.

5. Steel structure building is a Good environmental protection effect. Construction greatly reduces sand, stone, and the dosage of the ash. Most of the used materials are recyclable or degradable, little rubbish produced steel frame structures.

6. By using AutoCAD, PKPM, MTS, 3D3S, Tekla Structures (X steel) and etc. the steel structure is designed exactly. a complex industrial buildings like office mansion, super marker, auto dealer shop, shipping mall, 5-star hotel all can be done. Serve to all customers.

7. Steel structure is widely used as steel structure industrial factory, steel frame warehouse, steel office building, steel structure gymnasiums building, steel aircraft hangars, metal framing shed, steel commercial workshop building, etc.

8. Steel structure is suitable for both single-story steel structure warehouse, or large-span steel workshop buildings and multi-story steel structures or high-rise steel metal buildings.

Components are prefabricated in the factory, the site only need assemble as per construction drawings, which greatly shorten the construction time.

9. Steel workshop is durable, easy to repair, only simple maintenance, design is beautiful and practical, with simple and smooth lines. Colorful wall panels are available in a variety of colors, and the walls can also be made of other materials, which are more flexible.

10. The cost of steel structure workshop is reasonable, lightweight, reduce the cost of the foundation, fast construction, comprehensive economic benefits are greatly better than the concrete building and block building.

Quote information

Could you tell me your requirement for your steel structure project?

Basic design requirements and design Load,

1. Project site location:

2. Overall dimension (length*width*eave height in meters):

3. Mezzanine of not? How many kgs of load per square meter on mezzanine?

4. Single-layer steel sheet wall or sandwich panel wall:

5. Snow load if applicable:

6. Wind speed/load:

7. Interior column allowed or not:

8. Overhead crane needed or not, capacity:

9. Any other particular requirements:

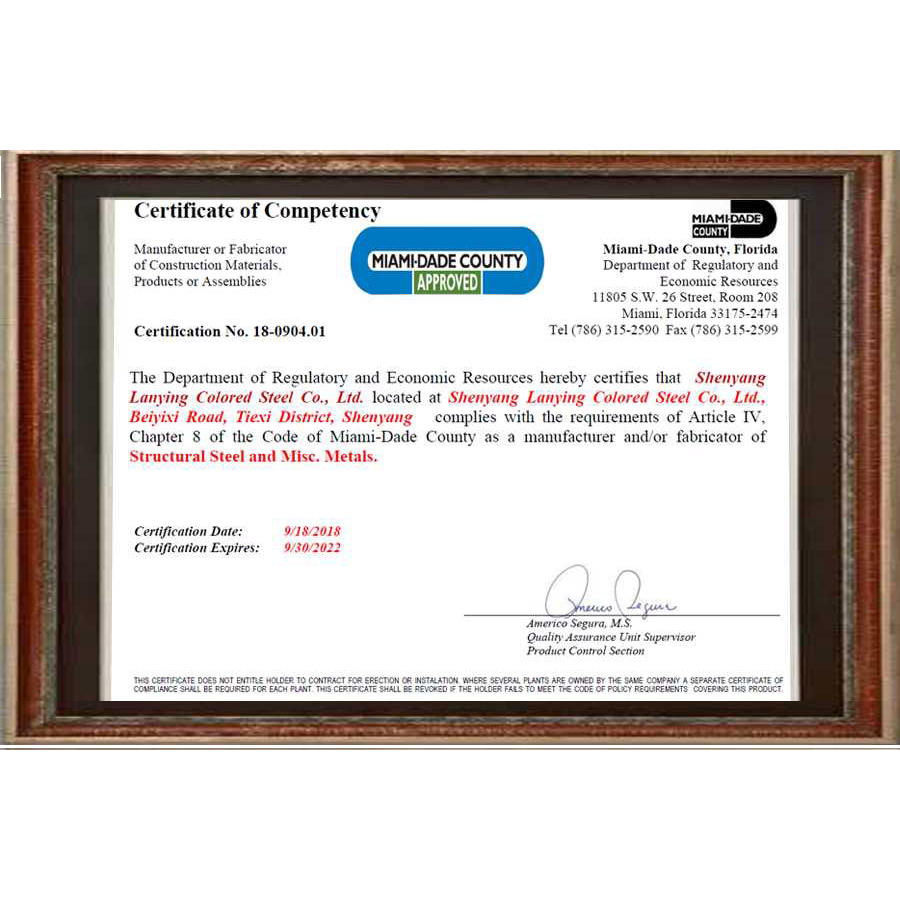

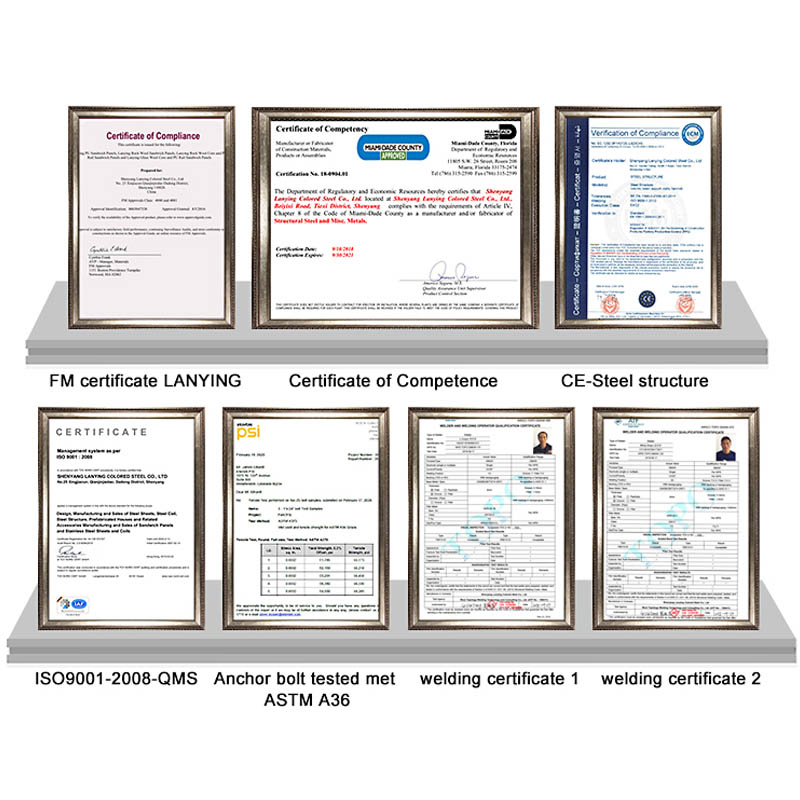

Certifications

Company Profile

Our group headquarters is located in Shenyang. Our manufacturing facilities are located in Liaoning, Shandong, Hebei, and Heilongjiang. We have the best quality of manufacturing equipment and a group of outstanding technical personnel. We have accumulated a wealth of practical experience in steel structure fabrication and installation and passed ISO9001:2000 quality management system certification.

With the purpose of “Market is the lead, Quality is the center, Treat the client with friendly service”, our company has become a modern enterprise integrating with manufacture and construction as a whole. Our company offers the whole set of services of all kinds of light steel buildings including design, manufacture, and construction. Our company emphasizes contract complying with credibility with rigorous product manufacturing processes.

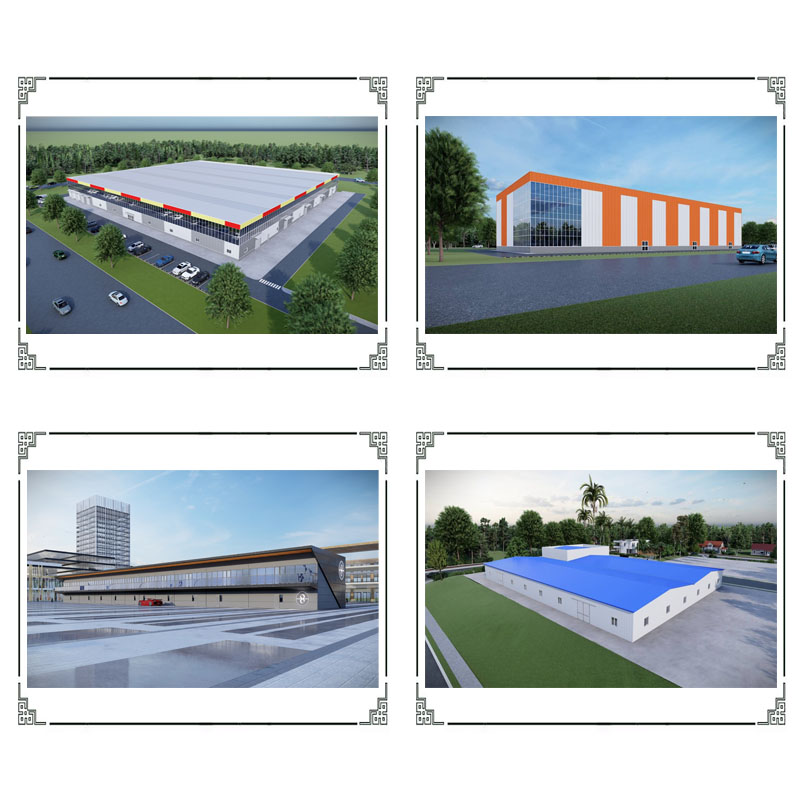

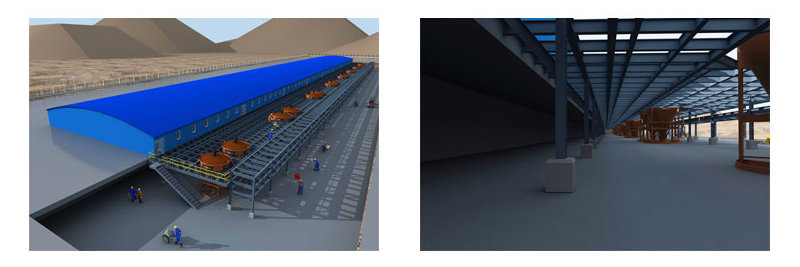

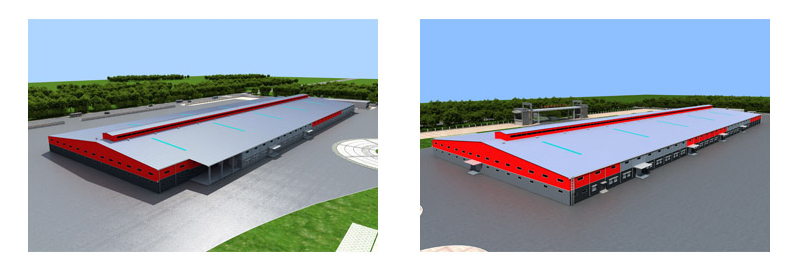

Project Cases

Steel structure building project in the USA

Steel structure building project in the Georgia

Steel structure building project in the Democratic Republic of the Congo

Steel structure building project in the Mozambique

Steel structure building project in the Togo