Metal Steel Structure Building Construction

Brand SYLY

Product origin China

Delivery time 30 working days

Supply capacity 5000 tons/month

1. Compared with ordinary reinforced concrete structures,metal shed construction have the advantages of homogeneity, high strength, fast construction speed, good seismic resistance and high recovery rate. The strength and elastic modulus of steel are many times higher than those of masonry and concrete. Therefore, Under the same load conditions, the weight of steel members is light. From the perspective of damage, the steel structure has a large deformation omen in advance, which belongs to the ductile failure structure, which can detect the danger in advance and avoid it.

2. The steel structure workshop metal steel building has the advantages of overall light weight, saving foundation, less materials, low cost, short construction period, large span, safety and reliability, beautiful appearance and stable structure. Steel structure workshops are widely used in construction industries such as large-span industrial plants, warehouses, cold storages, high-rise buildings, office buildings, multi-storey parking lots and residential buildings.

Quick Details

Type | Metal Steel Structure Building Construction | Warranty | 3 years |

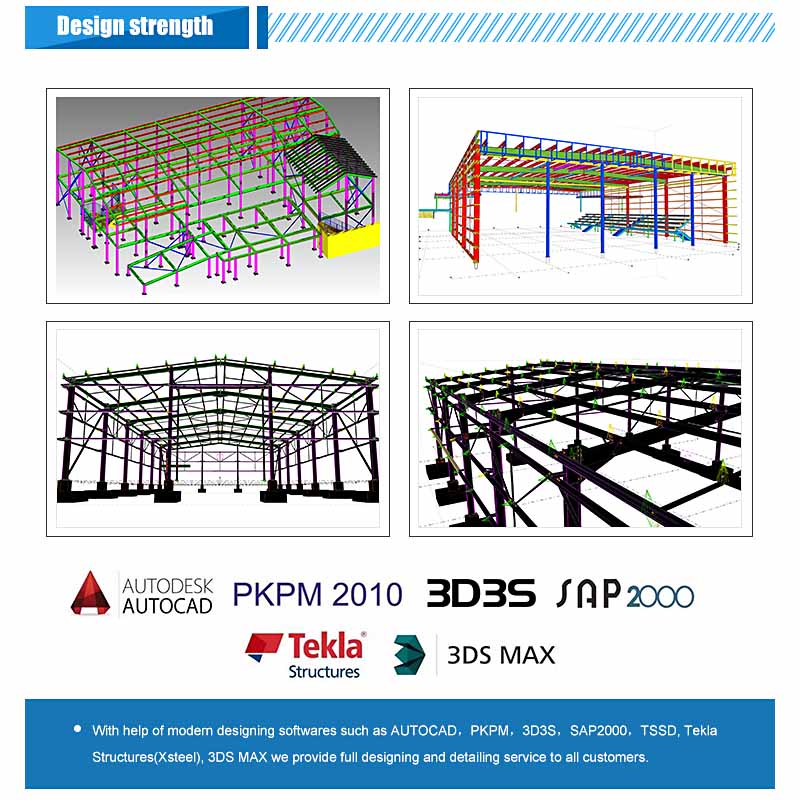

Afrer-sale Service | Online technical support Onsite Installation Onsite Training Onsite Inspection Free spare parts, Teturn and Replacement | Project Solution Capability: | graphic design 3D model design Total solution for projects Cross Categories Consolidation |

Standard | GB standard | Design Style | Transitional |

Place of Origin | Liaoning, China | Brand Name | SYLY |

Certificate | ISP9001:2008 | Purlin | C shape purlin |

Wind loading | 200km/h | Life time | 50 years |

Surface treatment | Anti-rust painting or galvanized | Door | Rolling door or sandwich panel door |

Roof and wall | Single layer sheet or sandwich panel | Window | PVC or aluminium window |

Products Description

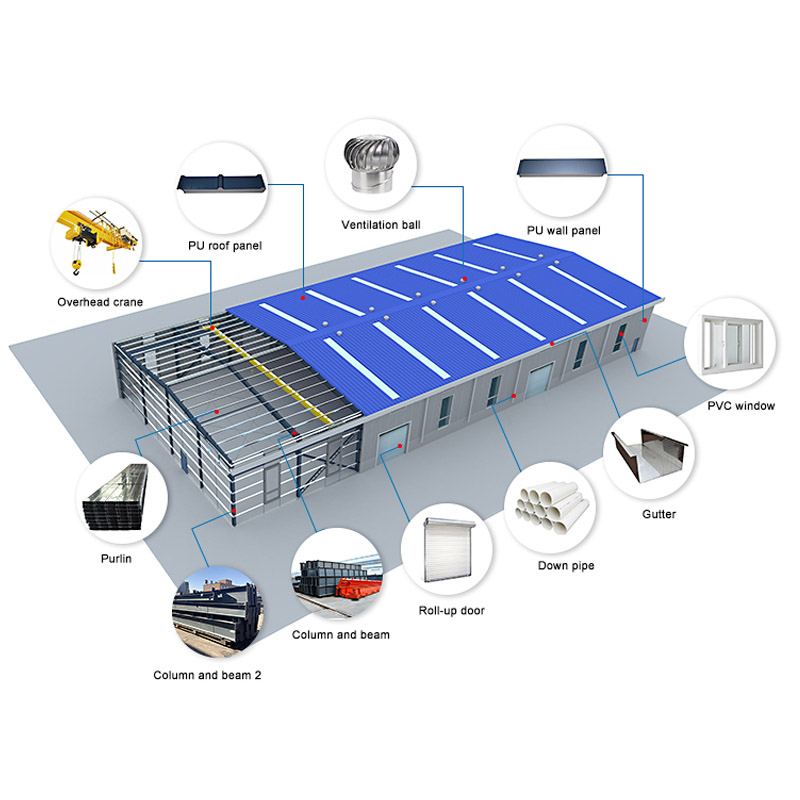

Items | Steel Workshop Buildings |

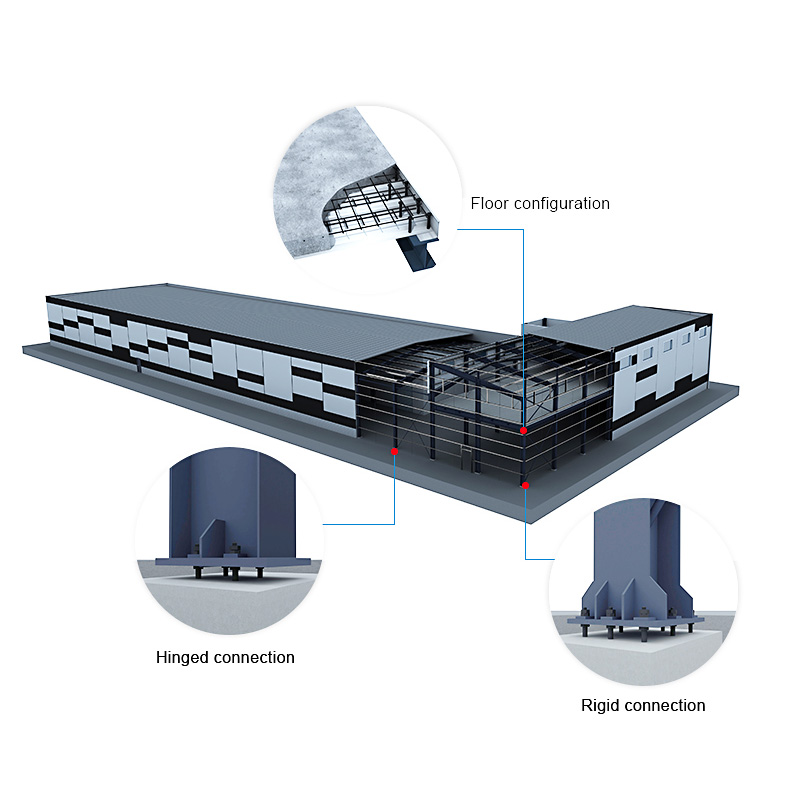

Main structure | PEB welded H-shaped steel or hot rolled steel, Q355 or Q235 |

Anti-rust protection | Hot dip galvanized or anti-rust painting |

Purlin and girts | Cold rolled C or Z steel, Q355 or Q235 |

Roof and wall | Single layer steel sheet or sandwich panel |

Gutter | Heavyduty galvanized steel |

Downpipe | PVC |

Door | Sliding door or roller shutter |

Windows | PVC or aluminum alloy |

Other components available upon request. Please provide the following information for detailed custom design. | |

Steel structure Workshop

Whether it’s for a business or private use, a metal workshop is a valuable addition to any property. General Steel provides the materials and resources to complete a professional building project that will thrive under any circumstances. Workshops are among the most popular buildings we sell because of the versatility, efficiency, and high-quality steel construction of a General Steel building.

1. Compared with ordinary reinforced concrete structures,metal shed construction have the advantages of homogeneity, high strength, fast construction speed, good seismic resistance and high recovery rate. The strength and elastic modulus of steel are many times higher than those of masonry and concrete. Therefore, Under the same load conditions, the weight of steel members is light. From the perspective of damage, the steel structure has a large deformation omen in advance, which belongs to the ductile failure structure, which can detect the danger in advance and avoid it.

2. The steel structure workshop metal steel building has the advantages of overall light weight, saving foundation, less materials, low cost, short construction period, large span, safety and reliability, beautiful appearance and stable structure. Steel structure workshops are widely used in construction industries such as large-span industrial plants, warehouses, cold storages, high-rise buildings, office buildings, multi-storey parking lots and residential buildings.

Quote information

Could you tell me your requirement for your steel structure project?

Basic design requirements and design Load,

1. Project site location:

2. Overall dimension (length*width*eave height in meters):

3. Mezzanine of not? How many kgs of load per square meter on mezzanine?

4. Single-layer steel sheet wall or sandwich panel wall:

5. Snow load if applicable:

6. Wind speed/load:

7. Interior column allowed or not:

8. Overhead crane needed or not, capacity:

9. Any other particular requirements:

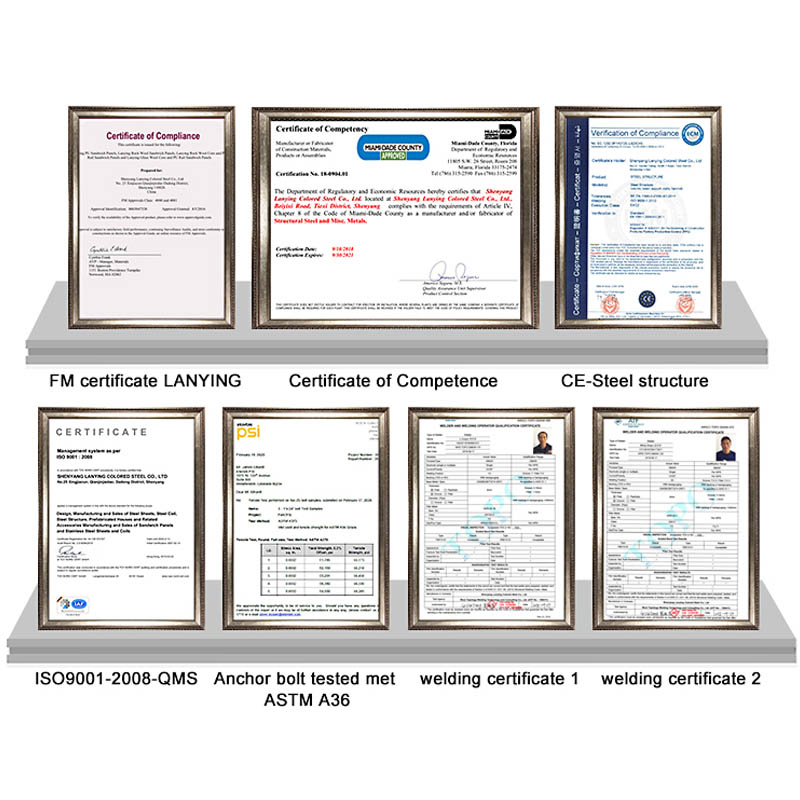

Certifications

Company Profile

Our group headquarters is located in Shenyang. Our manufacturing facilities are located in Liaoning, Shandong, Hebei, and Heilongjiang. We have the best quality of manufacturing equipment and a group of outstanding technical personnel. We have accumulated a wealth of practical experience in steel structure fabrication and installation and passed ISO9001:2000 quality management system certification.

With the purpose of “Market is the lead, Quality is the center, Treat the client with friendly service”, our company has become a modern enterprise integrating with manufacture and construction as a whole. Our company offers the whole set of services of all kinds of light steel buildings including design, manufacture, and construction. Our company emphasizes contract complying with credibility with rigorous product manufacturing processes.

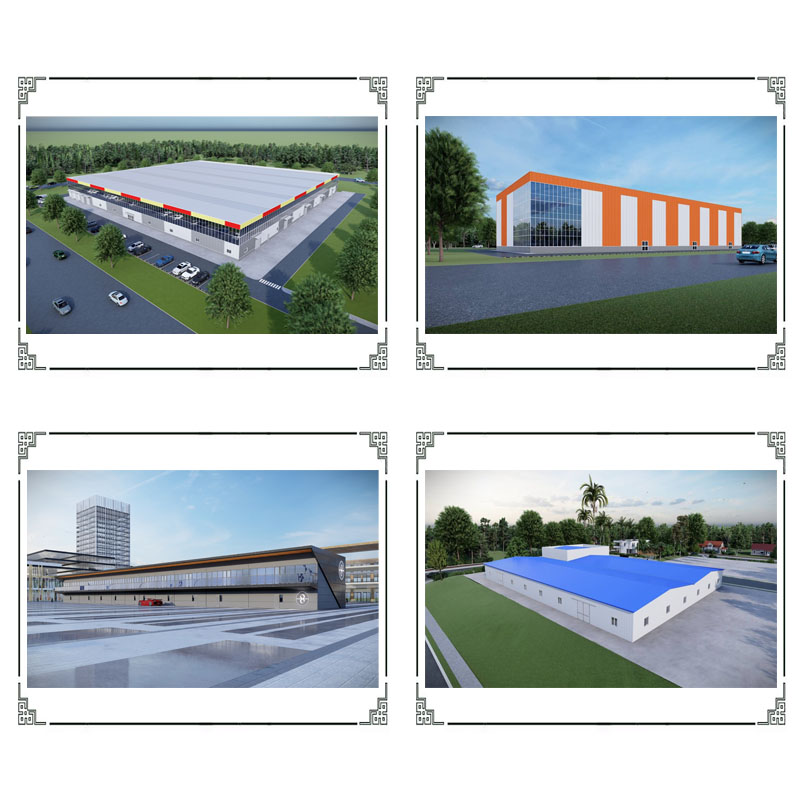

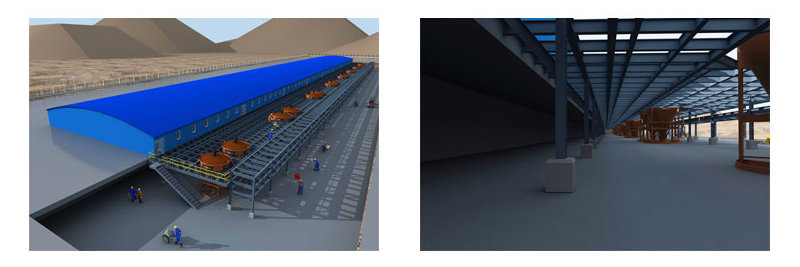

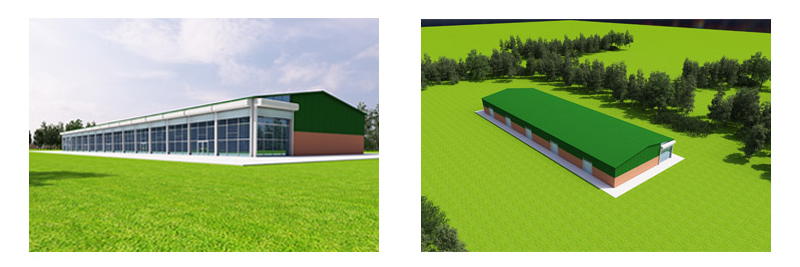

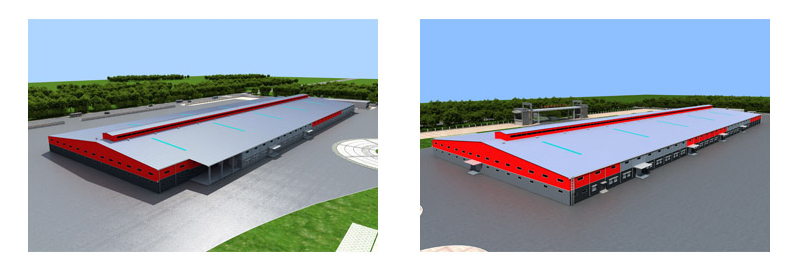

Project Cases

Steel structure building project in the USA

Steel structure building project in the Georgia

Steel structure building project in the Democratic Republic of the Congo

Steel structure building project in the Mozambique

Steel structure building project in the Togo