Prefabricated Industrial Storage Shed Cost

Brand SYLY

Product origin China

Delivery time 30 working days

Supply capacity 5000tons/month

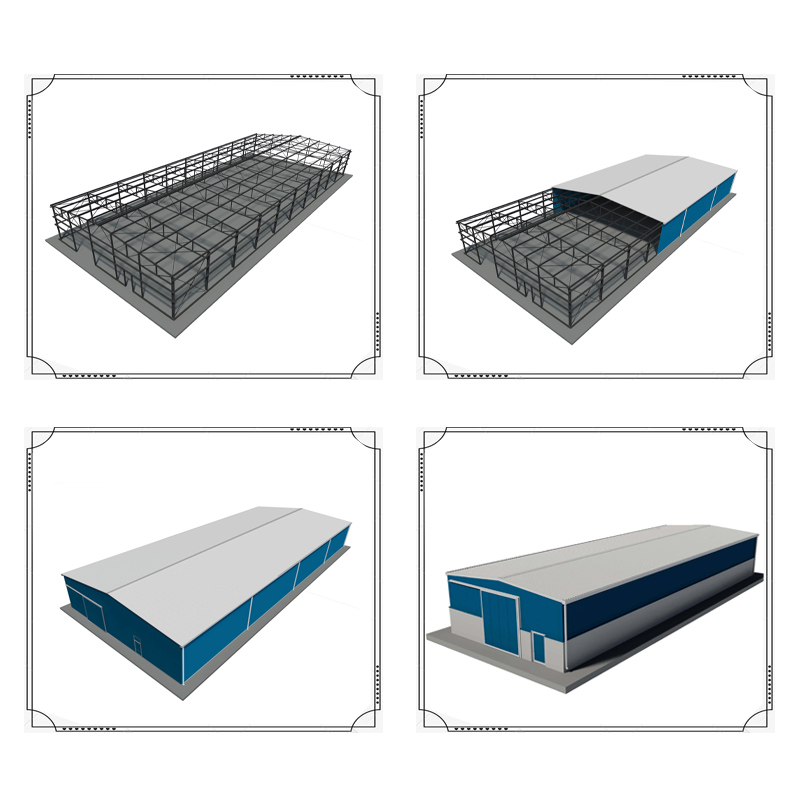

1. It is easy to add another section to the prefabricated industrial storage shed cost if you need more space or disassemble it and more it with you if need to be in another location. That will save a lot of material and time for people.

2. Prefabricated industrial storage shed cost is widely used for its convenience and low cost. Easy to assemble and disassemble for several times without damage. high efficiency, lower cost, great flexibility, fire and wind protection, lighting, and shock protection.

3. The prefabricated industrial storage shed cost can save effective using space Because the steel structure buildings can be designed in various shapes and are suitable for long-span structures. And can be designed without a central column. Multifil uses in many areas.

Product Name | Prefabricated Industrial Storage Shed Cost |

Main Steel Frame | H section steel beam and columns, painted or galvanized, galvanized c section or steel pipes. |

Secondary Steel Frame | Hot dip galvanized c purlin, steel bracing, tie bar, knee brace, edge cover, etc. |

Roof or Wall Panel | EPS sandwich panel, glass wool sandwich panel, rock wool sandwich panel, and PU sandwich panel or corrugated steel sheet. |

Tie Rod | Circular steel tubes |

Brace | Round bar |

Knee Brace | Angle steel |

Roof Gutter | Color steel sheet |

Windows | PVC frame or aluminum alloy frame windows |

Doors | Sliding sandwich panel door or rolling metal door or vertical hinged door |

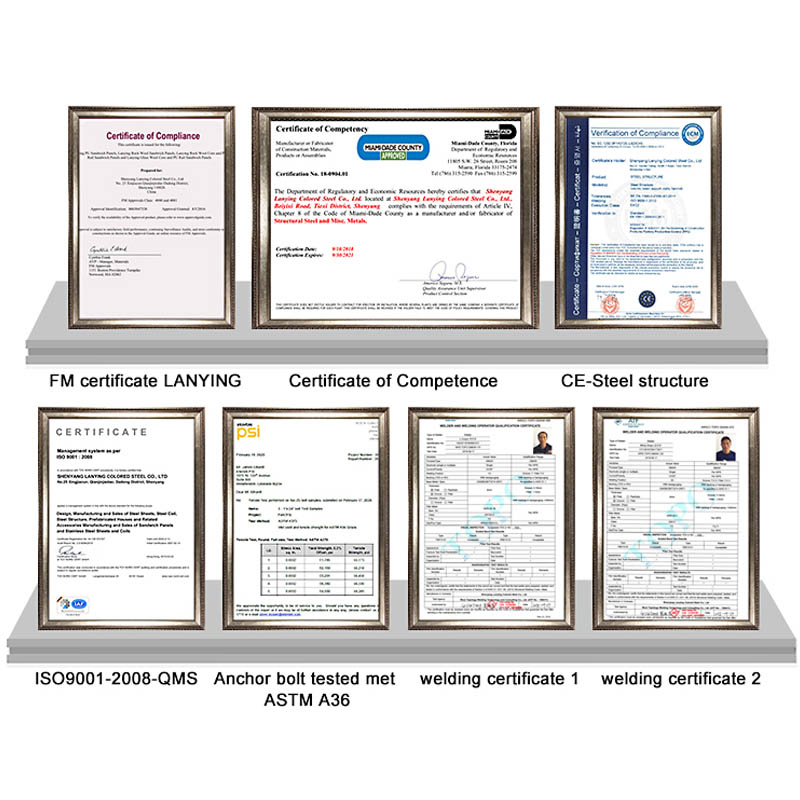

Certification | CE, SGS, ISO9001:2015, ISO 14001:2015 |

Connecting | Post feet bolts, anchor bolts, intensive bolts and machine bolts |

Packing | According to the pack list made by our engineer |

Drawings | CAD drawings |

Quotation | We can make the design and quotation according to your require or your drawing. |

Products Description

Warehouse construction material can be a industrial, agricultural or commercial building for storage or production of goods, often have cranes and forklifts for moving goods around the structures.

It requires easily transported, fast assembled without skilled labor, without affecting the quality and durability. And design allows for strength and sturdiness, protection against earthquakes and wind, and is relatively cheaper when compared to other material building. Warehouse construction material widely applied to warehouse, factory, workshop, storage, hangar, other steel buildings., also you can add the partition wall or first floor( second floor) according to multi-purpose.

Warehouse construction material adopts Q345B welded H type steel, Q345B steel square tube, Q235B C type steel and Q235B Z type steel to combine or build framework. Roof and wall are color compressing corrugated steel sheet or color steel sandwich panel.

Q345B is one of low carbon alloy steel. Welded H section Q345B steel with high strength, stronger buckling resistance performance, can save 10%-15% material, 30%-40% weight of structure in buildings and 15%-20% weight of structure in bridge than hot-rolled H steel. Compare to hot-rolled H steel, welded H section steel have high-accuracy size performance, can be customized.

Steel structure building not only has advantages of rust protection, acid resistance, good insulation performance, but is also neat and artistic. What's more, the steel structure is also famous for its conformation with the principles of physics, easy structure high efficiency, lower cost.

Certifications

Company Profile

Our group headquarters is located in Shenyang. Our manufacturing facilities are located in Liaoning, Shandong, Hebei, and Heilongjiang. We have the best quality of manufacturing equipment and a group of outstanding technical personnel. We have accumulated a wealth of practical experience in steel structure fabrication and installation and passed ISO9001:2000 quality management system certification.

With the purpose of "Market is the lead, Quality is the center, Treat the client with friendly service", our company has become a modern enterprise integrating with manufacture and construction as a whole. Our company offers the whole set of services of all kinds of light steel buildings including design, manufacture, and construction. Our company emphasizes contract complying with credibility with rigorous product manufacturing processes.

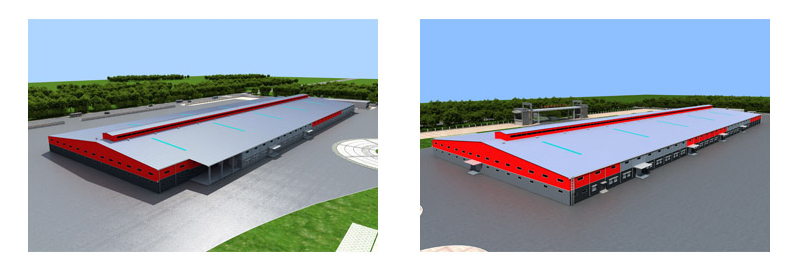

Project Cases

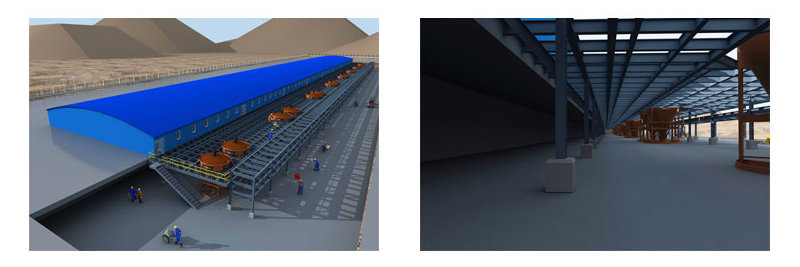

Steel structure building project in the USA

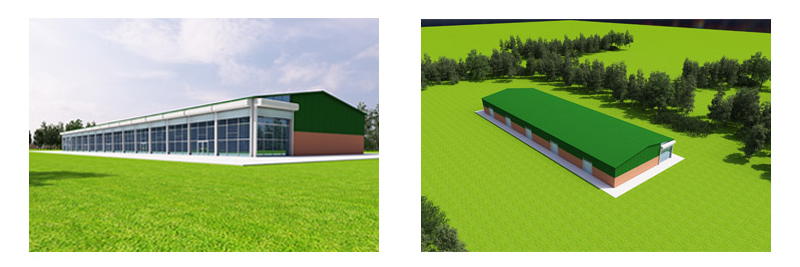

Steel structure building project in the Georgia

Steel structure building project in the Democratic Republic of the Congo

Steel structure building project in the Mozambique

Steel structure building project in the Togo