Prefabricated Steel Structure Workshop

Brand SYLY

Product origin China

Delivery time 30 working days

Supply capacity 5000 tons/month

1. The strength of prefabricated steel structure workshop is higher than traditional brick and concrete structures. Steel structure buildings are also much stronger than a traditional wood structures. So, it can build more structures higher than traditional building materials.

2. The lightweight of prefabricated steel workshops material its-self., compared with traditional steel-reinforced concrete, steel structure has the advantage of lightweight material its-self. The self-weight of the building is only one-fifth of that of the brick concrete structure.

Quick Details

Type | warehouse | Warranty | 3 years |

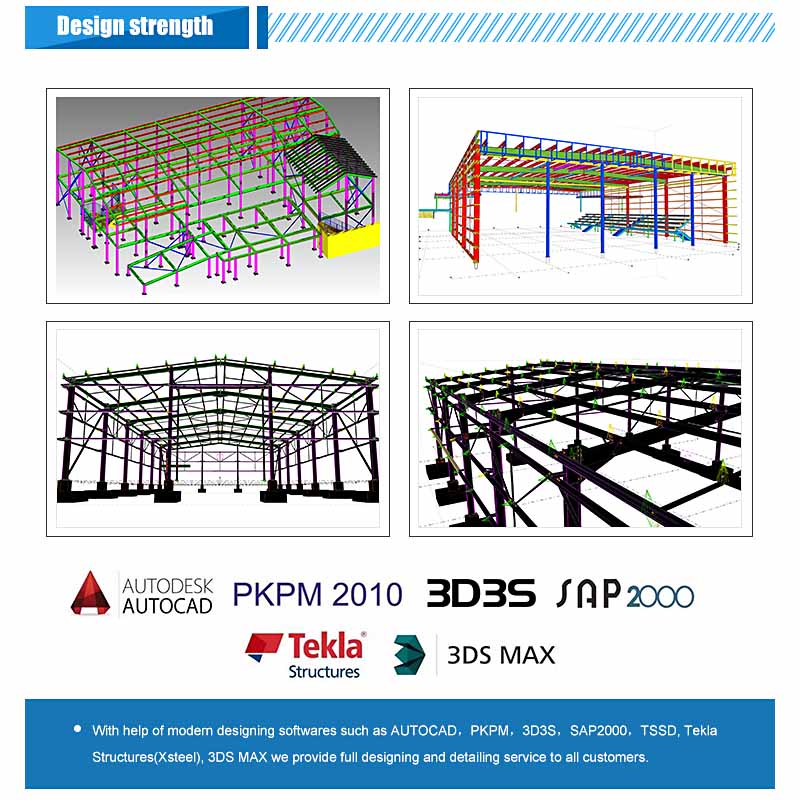

Afrer-sale Service | Online technical support Onsite Installation Onsite Training Onsite Inspection Free spare parts, Teturn and Replacement | Project Solution Capability: | graphic design 3D model design Total solution for projects Cross Categories Consolidation |

Standard | GB standard | Design Style | Transitional |

Place of Origin | Liaoning, China | Brand Name | SYLY |

Certificate | ISP9001:2008 | Purlin | C shape purlin |

Wind loading | 200km/h | Life time | 50 years |

Surface treatment | Anti-rust painting or galvanized | Door | Rolling door or sandwich panel door |

Roof and wall | Single layer sheet or sandwich panel | Window | PVC or aluminium window |

The lightweight of prefabricated steel workshops material its-self., compared with traditional steel-reinforced concrete, steel structure has the advantage of lightweight material its-self. The self-weight of the building is only one-fifth of that of the brick concrete structure.

1. Steel structure building is lightweight, high strength, safe and reliable, wind and earthquake resistant, good quality, and reliable. It has an accurate size, a beautiful outlook, long using lifespan. It is very easy and fast to install.

2. Steel structure materials can be recycled, and environmental pollution can be reduced when steel buildings are dismantled. Steel frame building is simple, the construction period is short, and saves labor costs.

3. Steel structure main beam and column are made of quality steel material Q355B Q345B Q235B, they make the building resist heavy wind, snow, and earthquake, cost-saving and transportation convenient, custom design available steel building.

4. Steel structure building widely used in construction site, office building, dormitory, warehouse, workshop, apartment, hangar, hall, storage shed. Easy assembly and disassembly several times without damaging steel structure shed.

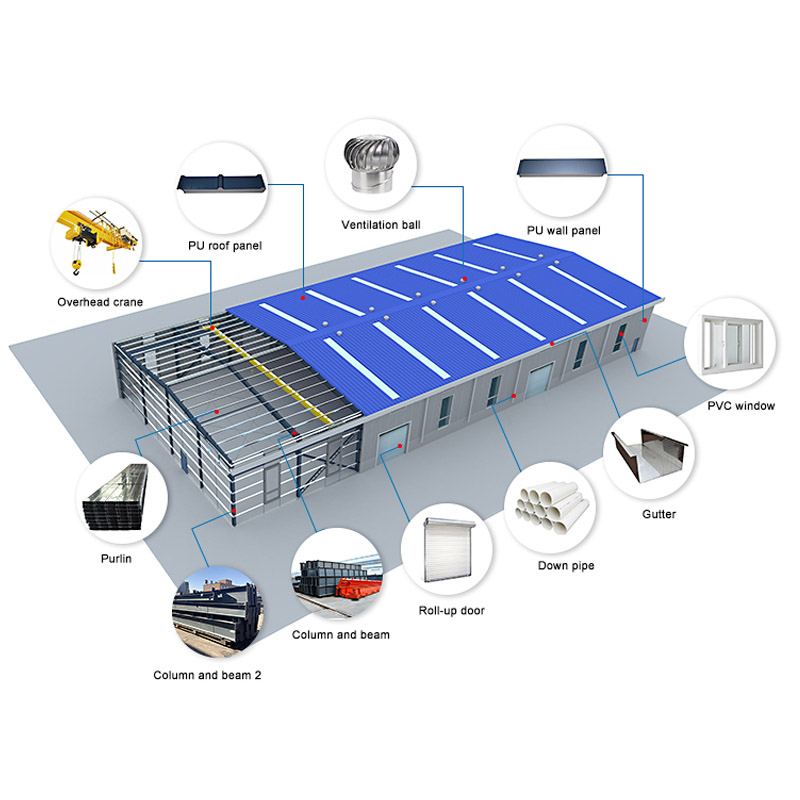

Products Description

Items | Specification |

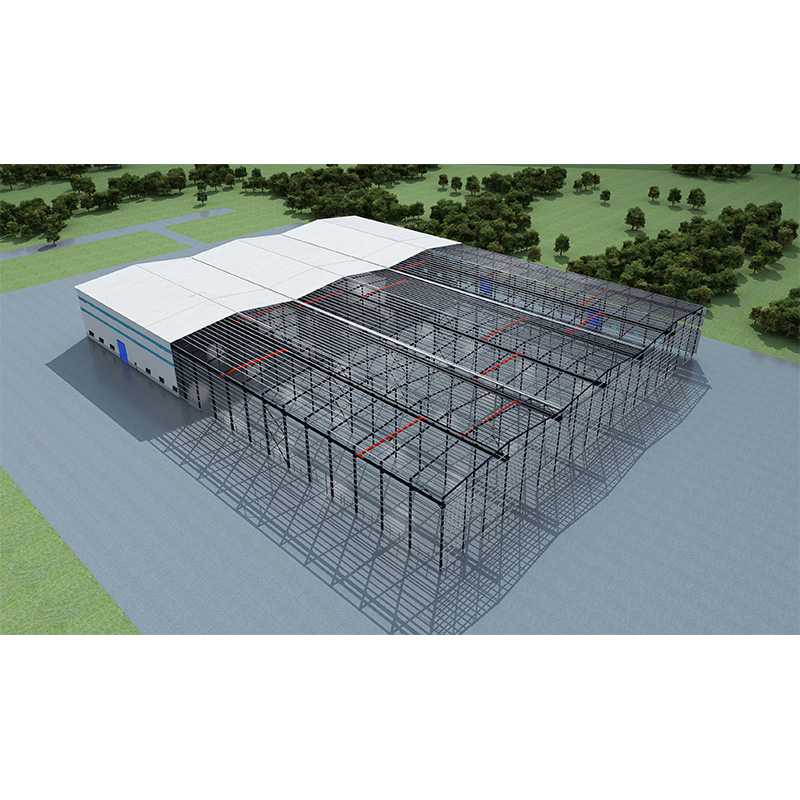

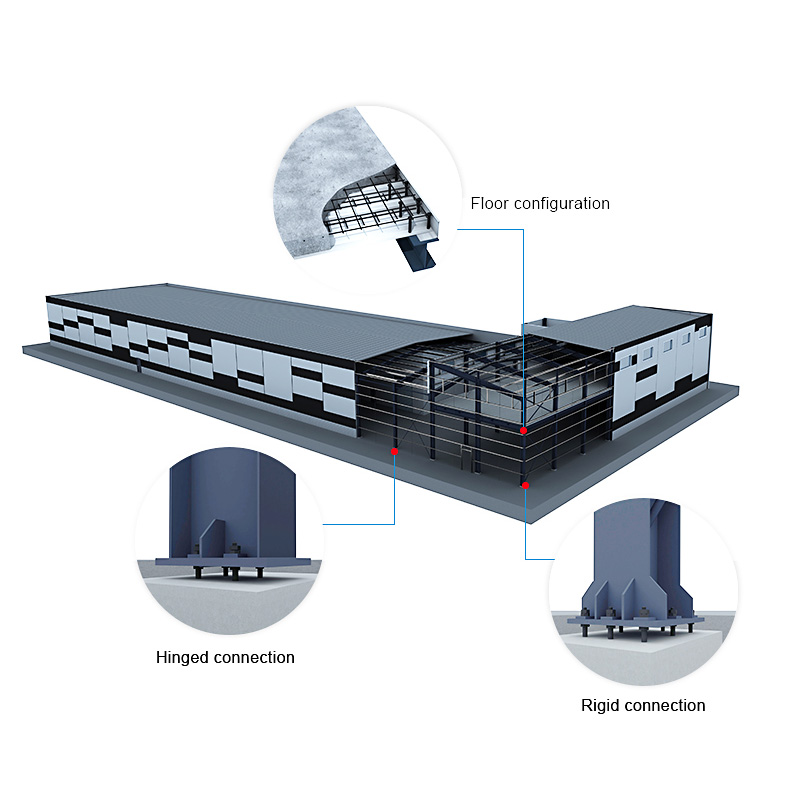

Main structure | PEB welded H-shaped steel or hot rolled steel, Q355 or Q235 |

Anti-rust protection | Hot dip galvanized or anti-rust painting |

Purlin and girts | Cold rolled C or Z steel, Q355 or Q235 |

Roof and wall | Single layer steel sheet or sandwich panel |

Gutter | Heavyduty galvanized steel |

Downpipe | PVC |

Door | Sliding door or roller shutter |

Windows | PVC or aluminum alloy |

Other components available upon request. Please provide the following information for detailed custom design. | |

The advantage of Steel Structure Warehouse

(Used in our China Manufacturers Prefabricated Warehouse Building Material Warehouse Price)

1. The tensile strength of steel is much more times greater than concrete.

2. Steel is also ductile in nature.

3. Steel has also the high strength to weight ratio as compared to concrete.

4. Steel structures are also preferred when time span is small. Construction rate is very fast.

5. Steel bars are also reusable.

6. Steel structures can be extended in any direction.

7. Steel has smaller columns as compared to concrete columns, so do to this more space will be available for some other functions.

8. As steel structures are lighter then concrete, therefore there is less cost used and foundation of structure become less expensive.

9. Steel structures are cost-effective

Building Purpose: we will recommend the best design for the purpose of the building

A.Warehouse/Storage

B.Factory

C.Agriculture Barn

D.Retail Store

E.Repair/Mechanic Shop

F.Office Space

G.Medical Warehouse

H.Animal Farm (please confirm what kind of animal)

Quote information

Could you tell me your requirement for your steel structure project?

Basic design requirements and design Load,

1. Project site location:

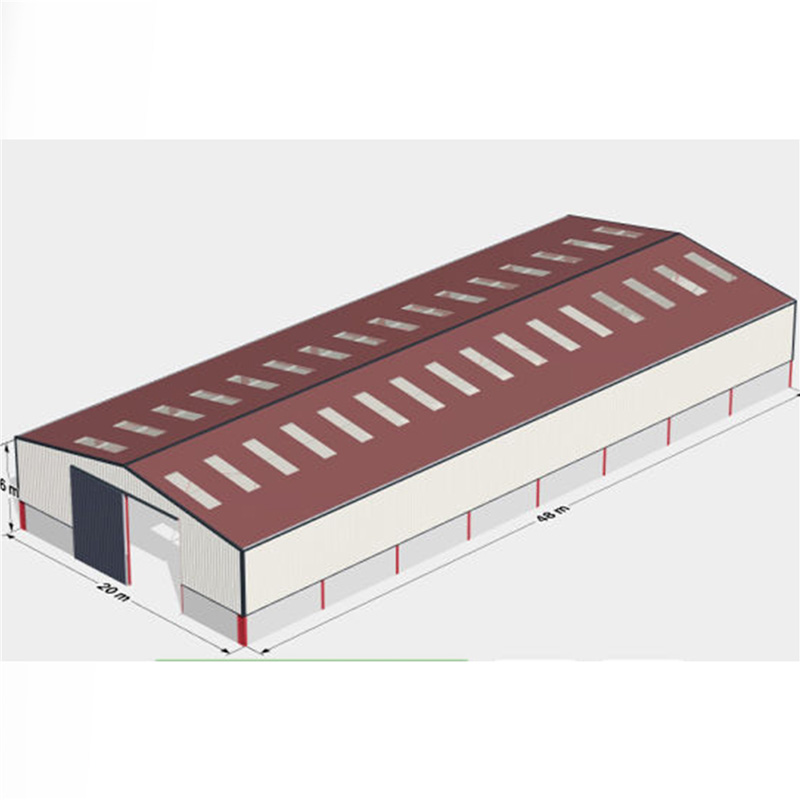

2. Overall dimension (length*width*eave height in meters):

3. Mezzanine of not? How many kgs of load per square meter on mezzanine?

4. Single-layer steel sheet wall or sandwich panel wall:

5. Snow load if applicable:

6. Wind speed/load:

7. Interior column allowed or not:

8. Overhead crane needed or not, capacity:

9. Any other particular requirements:

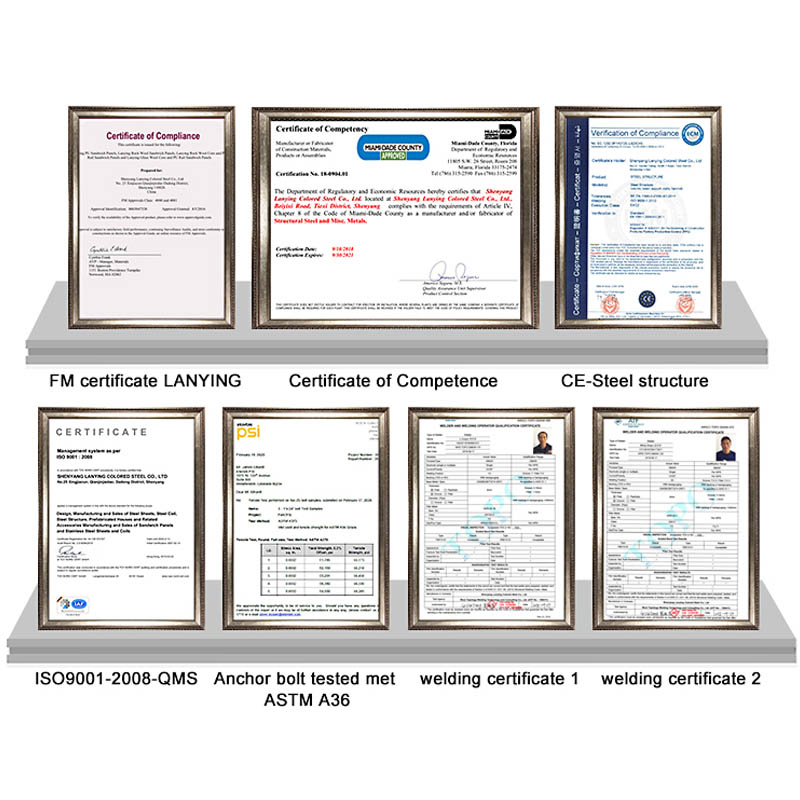

Certifications

Company Profile

Our group headquarters is located in Shenyang. Our manufacturing facilities are located in Liaoning, Shandong, Hebei, and Heilongjiang. We have the best quality of manufacturing equipment and a group of outstanding technical personnel. We have accumulated a wealth of practical experience in steel structure fabrication and installation and passed ISO9001:2000 quality management system certification.

With the purpose of “Market is the lead, Quality is the center, Treat the client with friendly service”, our company has become a modern enterprise integrating with manufacture and construction as a whole. Our company offers the whole set of services of all kinds of light steel buildings including design, manufacture, and construction. Our company emphasizes contract complying with credibility with rigorous product manufacturing processes.

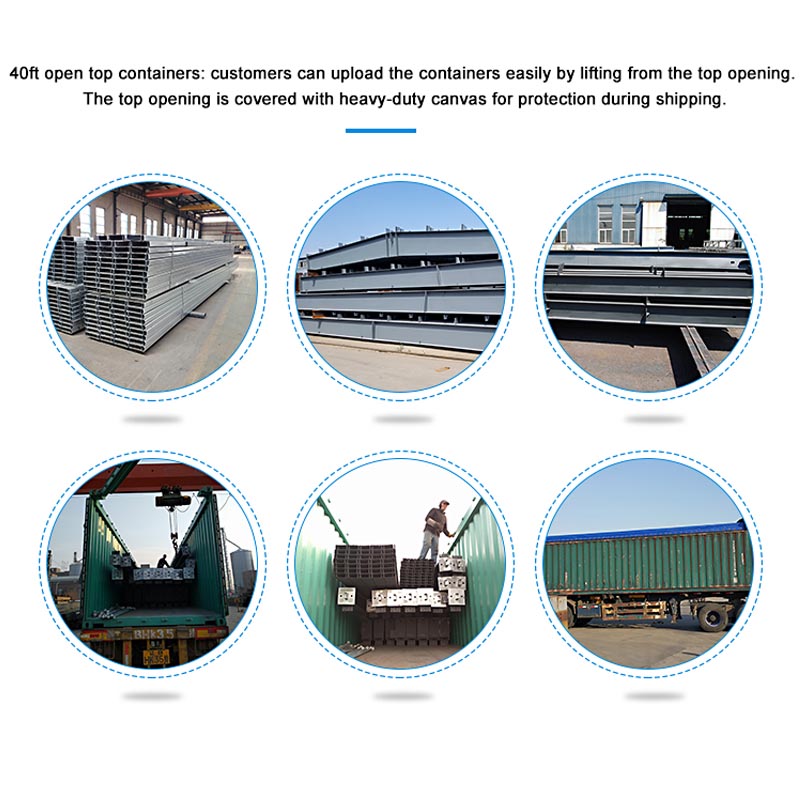

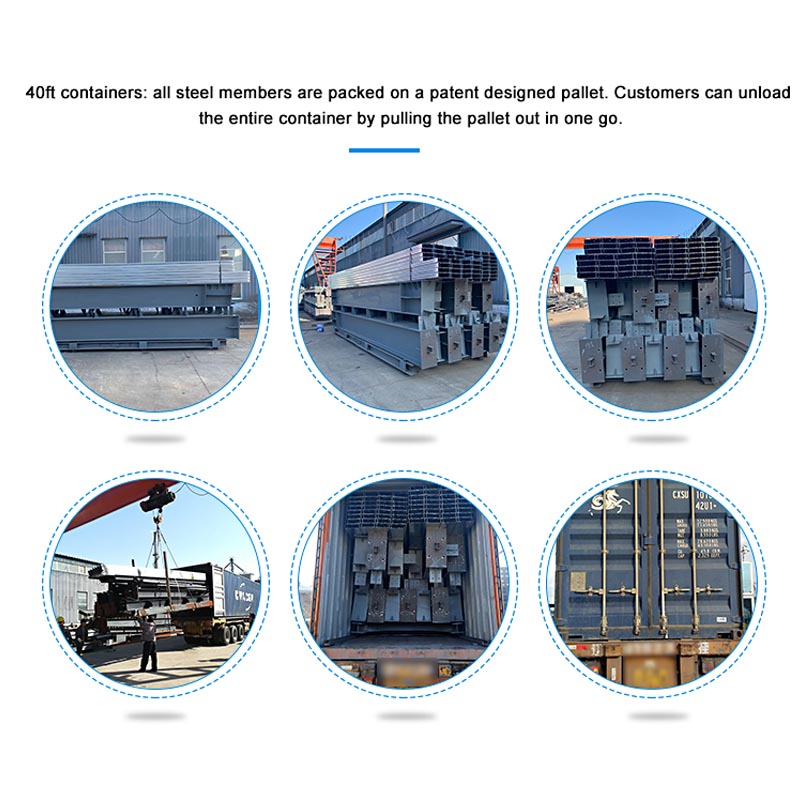

Packing Logistics

Fixed packing, loading, transportation, unloading the matters needing attention:

(1) The lifting large there must be a person responsible for the use of fixture, suitable, strictly abide by the rules of lifting, to prevent the occurrence of vibration, impact, deformation or damage, fall in the hoisting process.

(2) At the time of loading, there must be a special supervision, check car number and packing, the car pile up securely, and to increase the necessary binding component loosening, prevent the loss.

(3) Remained stable in the transport process, the vehicle at the time of shipment, on the long, wide, high object transport, must be trained pilots, escort personnel responsible for, and mark is arranged on a vehicle.

(4) No rough handling, loading and unloading personnel handling, weight, size should be familiar with the components, and check the horse sling, rigging, prevent accidents.

(5) The member to the construction site, timely organization of unloading, stacking area.

(6) The crawler crane carrying member, should pay attention to the surrounding terrain, air condition, prevent the crawler crane overturning and component collision.

Project Cases

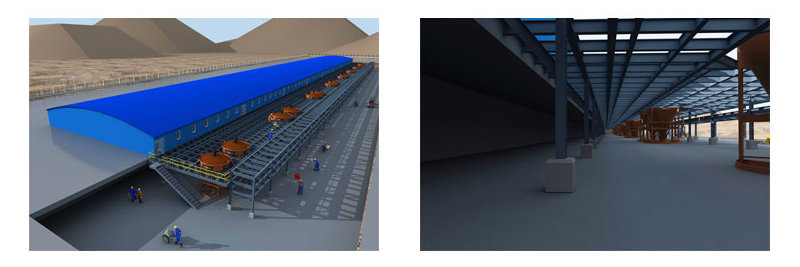

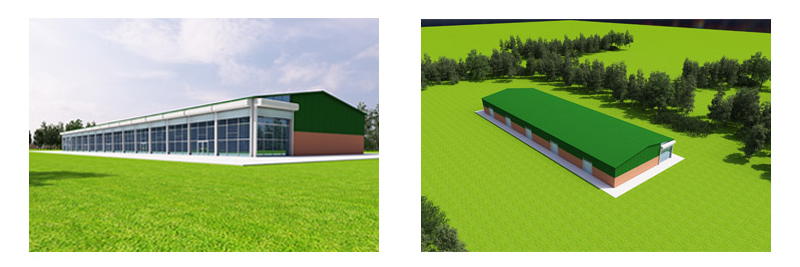

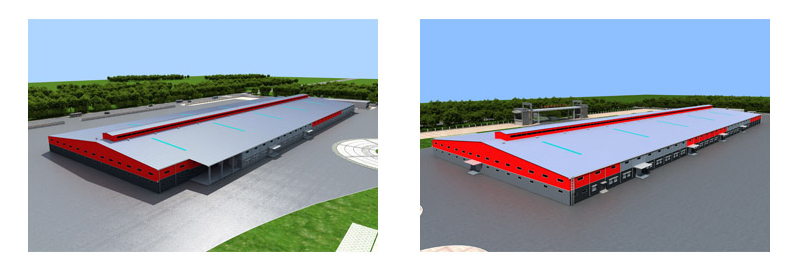

Steel structure building project in the USA

Steel structure building project in Georgia

Steel structure building project in the Democratic Republic of the Congo

Steel structure building project in Mozambique

Steel structure building project inTogo